The Genesis of a Product Line

In nuclear power plants, tools, helmets, and other personal items used inside a Radiologically Controlled Area (RCA) can potentially become contaminated with radioactive material. Typically, identifying these objects at the boundary of the RCA is achieved using devices known as small or large object monitors. Many plants have out-of-pocket policies requiring any and all items be screened prior to exiting the RCA.

These monitors use a combination of sensitive detectors surrounded by shielding, in an effort to balance the needs of accurate detection while eliminating any extraneous background radiation measurements.

In 2013, Electricité de France (EDF), the world's largest operator of nuclear power plants with 58 operating reactors in France alone, launched a public tender for a new generation of small object monitors which would progressively replace their current monitors, while gradually integrating newer monitoring technology.

The objectives of this new technology include:

- The ability to achieve lower alarm thresholds

- Reduction in measurement times

- Better adaptation to background conditions

- The ability to be used in a variety of industrial environments

In addition to these requirements, EDF also requested additional optional features, such as categorization of contamination type and functional improvements with enhanced ergonomics.

The Solution

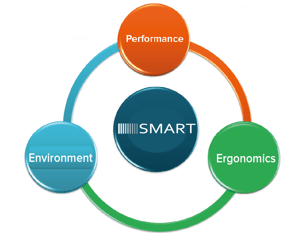

After examining these requirements, Mirion Technologies put several decades of radiation detection expertise to work and developed a new platform for contamination monitors. This new Smart Technology platform provides innovative answers to EDF’s needs in both detection accuracy and signal processing. It allows for operators at access control points to benefit from increased performance in a variety of areas, including ease of operation, improved acquisition of data, and operability in a wide variety of nuclear environments.

These improvements are accomplished through the implementation of spectrometry using plastic scintillation detectors and improved algorithms. This allows for highly accurate measurements to be taken, then analyzed quickly and efficiently, identifying both the presence of radioactive contamination and also the specific nature of it. This helps eliminate false alarms and wasted time conducting follow up surveys.

Operation is simple. An internal camera detects the presence of an object inside the chamber, and triggers detection with the input of key information on large touch screen monitors. Additionally, analysis and configuration functions are available, protected by a secure password hierarchy, offering detailed historical measures and background information that are important to supervisors for reporting purposes, but are less critical for typical operational situations.

Some Key Features of Smart Technology Include:

|

Measurement time optimization |

|

Rapid, dynamic adjustment based on background variations |

|

Intuitive and user-friendly interface |

|

Contamination Categorization (NORM and corrected activity)

|

|

Smart Item presence detection (internal camera / scale)

|

Spectrometry: A New Tool For Controlling Contamination

Incorporating plastic scintillators into the design allows for gamma spectrometry, which is a key feature of the new platform. Smart Technology realizes performance gains across a number of factors: spectrometry, detection sensitivity, and processing.

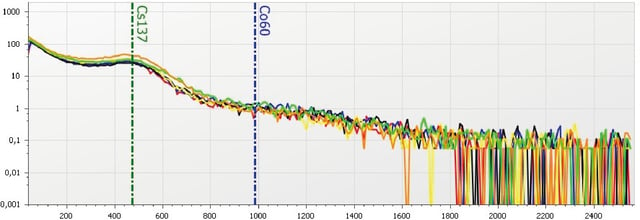

Notably, the organic scintillators used provide an economical method for achieving necessary detection results. Each of the (up to six) detectors has its own dedicated multi-channel analyzer, with signal samples stored in an integrated circuit. Additionally, results from multiple detectors are analyzed for similar timing, in order to generate a clear statistical picture.

Gross spectra of 6 detectors for a Cs-137 source

The spectra from the six detectors are calibrated to the same gain, meaning that all detectors will record the same energy levels in the same way. They are then added together in order to obtain a full-channel spectrum. The spectra measurements are also placed into FIFO (First In, First Out) storage every one hundred seconds for later retrieval and analysis.

This new method allows agile response to extremely dynamic background levels that are typical in the nuclear industry. During the background acquisition period, stored readings are inspected every second to allow comparison of short or long-lasting variations, ultimately allowing the elimination of brief variations in background radiation. In addition, anomalies can be easily detected during measurement. Typically, this leads to a reassessment of the measurement in progress, which helps the monitor to anticipate its decision of contamination or non-contamination.

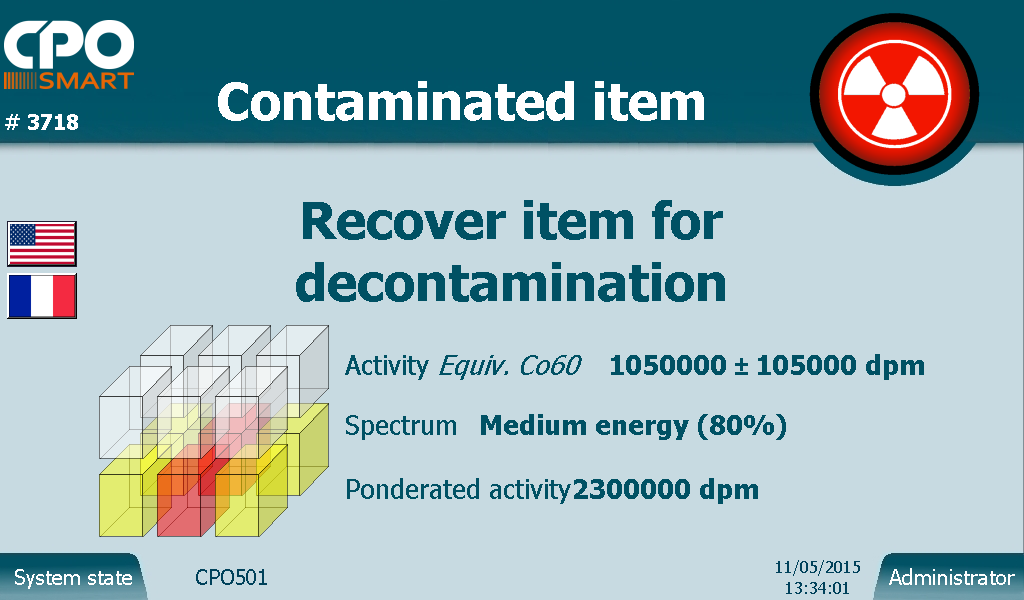

Example of displayed results for an item contaminated with CS-137

Performance Results

Better consistency of measurement results throughout the entire detection volume, with reduced dead zones and a homogeneity between +5% and -10 % has been established in testing of the CPO-Smart with 6-detectors.

Isotopic Categorization

Initially, the isotopes will be categorized within three dominant energy classes (low, medium and high) and a NORM class (Naturally Occurring Radioactive Material).

- The high energy class is any measurements greater than 1 MeV (primarily Cobalt 60)

- The medium energy class, corresponding to Cobalt 58, Silver 110m and Zirconium 95, is primarily represented by Cesium 137.

- The low energy class corresponds to Iodine 131 and Cobalt 57. These mixtures are indicated as percentage content.

- In the case of Naturally Occurring Radioactive Material, the term NORM is displayed if the statistical accuracy is sufficient.

Isotopic Identification

Mirion Technologies has developed a processing technique which restores a classical photoelectrical spectrum and allows individual identification of isotopes. In the case of long-term temperature variations, obtained spectra are also useful for stabilizing the operating temperature.

The limits of detection and/or the duration of measurement can be reduced based on variations of the spectrum at a particular site. For example, the detection of Cobalt 60 in very high background environments is facilitated by the detection of coincidences, in which multiple detectors identify the same signature at the same time. This type of coincidence counting is an indirect benefit of using multi-channel spectrometers.

The Smart Product Line

This new performance capability allowed Mirion Technologies to design a range of products focused on various industry challenges and operational requirements.

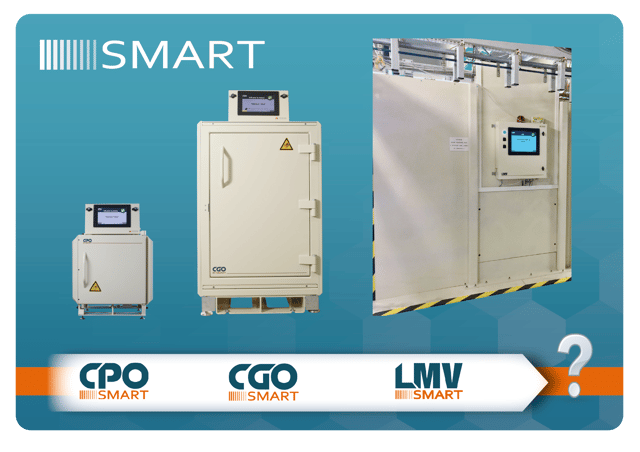

CP O-Smart

O-Smart

This new generation of small object monitor was designed to address the more demanding technical and regulatory constraints of the nuclear industry by making it easy to use and delivering highly accurate performance. Features a 36 liter detection chamber.

CGO-Smart

The CGO-Smart is the large-scale version of the CPO-Smart, featuring a detection volume of 307 liters.

Designed for screening large objects, its high quality and measurement speed make it an extremely useful monitor for access control points.

LMV-Smart

LMV-Smart is a contamination monitor designed for high speed laundry monitoring in a vertical position, using a conveyor system for hanging clothes.

Its size was designed to accommodate the protective clothing in the nuclear industry, with modular shielding to maintain consistent geometry and environmental conditions.

A Gateway to the Future ...

Smart Technology was developed from a a combination of advancements in detection technology coupled with improved human factors, resulting in easier operation and better adaptability to dynamic environments.

Copyright (c) 2016 Mirion Technologies, Inc. or its affiliates. All rights reserved. Mirion, the Mirion logo, and other trade names of Mirion products listed herein are registered trademarks or trademarks of Mirion Technologies, Inc. or its affiliates in the United States and other countries. Third party trademarks mentioned are the property of their respective owners.